GATHERING RESEARCHERS

Casting and Molding Technology; Regional Innovation Strategy Supported Theme

①

Theme |

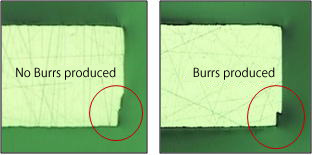

Development of Burrs-less Press technology and specific Insert Mold Technology |  |

Category |

Die technology Mold technology |

|

Responsible |

Iwate University Hirose kouichi Prof. |

|

Researcher |

Iwate University Otsuki Kazutoshi Prof. |

|

Contents |

Development of Burrs-less Press technology & Insert mold technology. Automotive high quality and low cost connectors are demanded, according to automotive electrification. This research develops, the Press method to produce Burrs-less precise metal parts, and the Insert-molding method to produce connector parts consist of metal and plastic for increasing quality, improving process cost. Iwate university lab and Iwate regional industries have enough experience and knowhow on making material process, die technology , molding technology and forming technology. These collaboration strengthens this research. |

|

Theme |

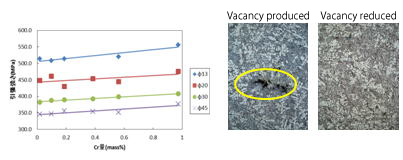

Development of Casting technology for high strength automotive materials |  |

Category |

Casting technology | |

Responsible |

Iwate University Hiratsuka Sadato Prof. |

|

Researcher |

Iwate University Shobuzawa Yoshiyuki Prof. |

|

Contents |

Development of Casting technology for high strength automotive parts. To clarify the strengthen effect of precise carbon elements, to develop the method to produce high strength and low weight casting parts for automobile. Iwate university lab has much experience and knowhow on inoculation technology, material technology and casting technology. Iwate univ. and Iwate industries are leading position on these technologies in Japan. This research develops high strength and low weight automotive casting parts, collaborated with Iwate industries. In concrete, targeted to develop over 350MPa specification on automotive casting parts. |

|

Casting and Molding Technology; Other related themes

③

Theme |

Development of Separating technology on Die |  Optical Plastic Lens |

Category |

Die technology | |

Researcher |

Iwate University Hirahara Hidetoshi Prof. |

|

Contents |

Development of technology to improve separating-ness on complex Die and plastic material. This research enables to make Die clean and durable, and enables to realize pressing process for parts with further complex shape. . | |

Application |

Optical parts manufacturing process, Electro-optic materials manufacturing process | |

Impact |

Improve separating-ness on Die and plastic material, it is possible to manufacture high quality precise Optical parts. | |

Theme |

Development of Separating technology on Die |  Triazine Thiols vapor deposition mechanism |

Category |

Die technology | |

Researcher |

Iwate Industry Research Institute Suzuki Kaztaka. |

|

Patent |

Patent No.4062537 Licensable |

|

Contents |

Thin film Triazine Thiols vapor deposed on the surface of solid materials. Improve separeting-ness and durability of the Die. |

|

Application |

Application: connector manufacturing process, gear manufacturing process, metal manufacturing process, watch manufacturing process, etc. | |

Impact |

Due to enhance Triazine Thiols’s adhesive activation on the surface, molecule level polymerization reaction utilized. | |

Theme |

Polymer coating |  |

Category |

Die technology | |

Researcher |

Iwate Industry Research Institute Suzuki Kaztaka. |

|

Patents |

Patent No.4982859 Licensable |

|

Contents |

Technology of organic material coating. According to cold spray method, by means of optimized collision process between mixed powder material of organic/non-organic and plastic plate |

|

Application |

Application: water repellent characteristics on the surface of connector, gears, metals parts. Besides possible to apply for reforming membranes. | |

Impact |

Keeping organic material low temperature by cold spray, improve degradation of organic materials. Even cold spray, this technology can strengthen connection between the materials and the plate. | |

Theme |

Development of Manufacturing method of Die |  Die manufacturing process |

Category |

Die technology | |

Researcher |

Iwate Industry Research Institute Kuwashima Takayuki, Sonoda Tetsuya. |

|

Patents |

Patent No.4737169 Licensable |

|

Contents |

To realize efficient Die manufacturing process and strengthened Die manufacturing process, by means of cold spray method | |

Application |

Application: Injection molding, Power slush molding, Rolling forming, RIM forming, RT forming | |

Impact |

To realize efficient Die manufacturing process and strengthened Die manufacturing process | |

Theme |

Development of Die shell |  Die shell : Thermo controlled parts-2 fixed on Die 1 |

Category |

Die technology | |

Researcher |

Iwate Industry Research Institute Kuwashima Takayuki, Sonoda Tetsuya. |

|

Patents |

Patent No.4737170 Licensable |

|

Contents |

Development of efficient manufacturing process of Die shell combined with thermo controlled parts, by means of cold spray. | |

Application |

Application: Injection molding, Power slush molding, Rolling forming, RIM forming, RT forming | |

Impact |

To realize efficient Die shell manufacturing process with less strain, less torsion, less shrink | |

Theme |

Strengthened Die |  Electroformed layer on Die 1 |

Category |

Die technology | |

Researcher |

Iwate Industry Research Institute Kuwashima Takayuki, Sonoda Tetsuya. |

|

Patents |

Patent No.4737188 Licensable |

|

Contents |

Development of manufacturing process of reinforced Die by means of cold spray focusing electroforming layer. | |

Application |

Application: To repair Die for Injection molding, Power slush molding, Rolling forming, RIM forming, RT forming | |

Impact |

Efficient repairing is possible, due to no masking process of electroforming layer and no making process of adhesive layer between electroforming and metal layer. | |

Theme |

Surface reformed resin |  Electron injector for resin reforming |

Category |

Die technology | |

Researcher |

Iwate Industry Research Institute Suzuki Kazutaka |

|

Patents |

Patent No.2009-227857 Licensable |

|

Contents |

Development of Thin film Resin reforming method not only by cold spray but also by Triazine Thiols deposed on surface of fluorocarbon polymers | |

Application |

Application: Surface reforming of Thin film resin, as anti-erosion treatment | |

Impact |

Due to Triazine Thiols deposed on the surface of resin, such resin works strong adhesiveness. | |

Theme |

Surface coating on Rasin |  Electron injector for resin reforming |

Category |

Die technology | |

Researcher |

Iwate Industry Research Institute Suzuki Kazutaka |

|

Patents |

Patent No.2009-226329 Licensable |

|

Contents |

Development of cold spray surface reforming process by using resin powder with Triazine Thiols deposed. | |

Application |

Application : resin coating | |

Impact |

Cold spray enables to improve thermal shock on resin, Triazine Thiols realize strong adhesiveness.. | |

Theme |

Die for Injection molding |  Thermal control structure on injection molding Die |

Category |

Die technology | |

Researcher |

Iwate Industry Research Institute Kuwashima Takayuki, Saito Takashi |

|

Patents |

Patent No.2010-201846 Licensable |

|

Contents |

Development of Thermal controllable structure on Die, by means of cold spray method | |

Application |

Application : Thermal controllable structure on Die for injection molding | |

Impact |

Efficient thermal control on Die surface | |

Theme |

Manufacturing Die shell | Electroforming shell, with thermal control piping |

Category |

Die technology | |

Researcher |

Iwate Industry Research Institute Kuwashima Takayuki, Saito Takashi |

|

Patents |

Patent No.2010-209389 Licensable |

|

Contents |

Development of Electroforming shell manufacturing process and less strain, less torsion, less shrink, less thermal loss, by means of cold spray | |

Application |

Application: Thermal controllable electroforming shell for Injection molding, Power slush molding, Rolling forming, RIM forming, RT forming | |

Impact |

To realize efficient Electroforming shell manufacturing process and less strain, less torsion, less shrink, less thermal loss | |

Theme |

Manufacturing Die shell |  Cold spray equipment |

Category |

Die technology | |

Researcher |

Iwate Industry Research Institute Kuwashima Takayuki, Sonoda Tetsuya |

|

Patents |

Patent No.2011-122213 Licensable |

|

Contents |

Development of high density coating method by using Laser beam injection | |

Application |

Application : repair of Die | |

Impact |

Surface coating Powder heated just before injection, makes high density coating | |

Theme |

Mold releasing |  Vacuum vapor disposition equipment |

Category |

Die technology | |

Researcher |

Iwate Industry Research Institute Suzuki Kaztaka |

|

Patents |

Patent No. 4567019 | |

Contents |

Surface treatment technology on Die specific for optical parts | |

Application |

Application : Surface treatment on Die which improve mold releasing performance | |

Impact |

Possible to realize high mold releasing, high quality coating on Die surface | |

Theme |

Composite material of casting iron |  Structure of composite material of casting iron |

Category |

Material technology | |

Researcher |

Iwate Industry Research Institute Ike Hiroyuki, Takagawa Takahito |

|

Patents |

Patent No.4020277 Licensable |

|

Contents |

Combination of Spheroidal graphite cast iron and Ductile graphite cast iron, apply for Die | |

Application |

Application : new product design | |

Impact |

High strength, high anti-erosion performance realized | |

Theme |

Mold releasing |  Vacuum vapor molding apparatus for metal surface treatment |

Category |

Material technology | |

Researcher |

Iwate Industry Research Institute Suzuki Kazutaka |

|

Patents |

Patent No.412447 Licensable |

|

Contents |

Method to develop long life mold releasable Die for epoxy forming, by using vacuum vapor deposition | |

Application |

Application : Coating with reforming function for connectors, gears, metal, Die, etc. | |

Impact |

Easy process to realize cross linkage performance on Polymer thin layer formed on metal surface | |

Theme |

Drawing press |  Bead in Drawing press |

Category |

Material technology | |

Researcher |

Iwate Industry Research Institute Sonoda Tetsuya |

|

Patents |

Patent No. 2010-125472 Licensable |

|

Contents |

Technology for 3D drawing press process (for automotive body panel etc) to control injecting material flow | |

Application |

Application : 3D drawing press process with controlling injecting material flow | |

Impact |

Increase durability of Bead and Reduce process of strengthen treatment | |

Theme |

Cutting press |  Cutter in Cutting press |

Category |

Material technology | |

Researcher |

Iwate Industry Research Institute Sonoda Tetsuya |

|

Patents |

Patent No.4913112 Licensable |

|

Contents |

In case of cutter strengthen process, develop low thermal impact process by using cold spray | |

Application |

Application : cutter strengthen process in cutting press of automotive body panels. | |

Impact |

Improve durability of cutter, less influence from thermal treatment | |

Theme |

Resin molding |  Molding Die |

Category |

Material technology | |

Researcher |

Iwate Industry Research Institute Kuwashima Takayuki, Saito Takashi |

|

Patents |

Patent No.2010-234756 Licensable |

|

Contents |

Low cost process for manufacturing Die, by using cold spray instead of vapor deposition kettle | |

Application |

Application : Manufacturing process of resin forming | |

Impact |

No vapor deposition kettle, but low cost manufacturing Die | |

Theme |

Processing technology by using Ultra sonic vibration |  |

Category |

Processing technology | |

Researcher |

Ichinoseki National College of Technology Hara Keisuke |

|

Patents |

Patent No.2010-234756 Licensable |

|

Contents |

In order to realize precise processing, processing of difficult-to-cut materials, new processing technology developed by using Ultra sonic vibration | |

Application |

Application : precise processing, processing of difficult-to-cut materials easy can be realized | |

Impact |

Processing is possible, with less worn of tool, with easy process of difficult-to-cut materials. | |